- Material:

- Polyester/wool/PVC or Customized

- Style:

- Plain

- Pattern:

- Plain Dyed

- Design:

- Persian

- Technics:

- Needle-punched nonwoven

- Use:

- Bathroom, Bedroom, Car, Commercial, Decorative, Home, Hotel, Outdoor, Prayer, Toilet

- Size:

- within 3.2m, 60''

- Place of Origin:

- Guangdong, China (Mainland)

- Brand Name:

- JinHaoCheng

- Model Number:

- Floor Carpet

- Sample:

- Free sample

- Color:

- Any color

- Thickness:

- 1-15 mm or Customized

- GSM:

- 60~1000gsm or Customized

- Certification:

- ISO9001/Oeko-Tex Standard 100/Standard RoHS

- Length:

- 100 m/roll or Customized

- Yarn Count:

- 3d-7d

- OEM:

- OEM design is availabe

- SupplyAbility:

- 12000 Kilogram/Kilograms per Day

- Packaging Details

- Packaging:Plastic packing outside,scroll in the roll.

20'FT container:5~6 tons ( the details quantity is up to the diameter of the roll).

40'HQ container:12~14 tons ( the details quantity is up to the diameter of the roll).

- Port

- Shenzhen

- Lead Time :

- 14-30 days upon receipt of 30% deposit

| Product Name | Hotel style carpet custom made plain nonwoven polyester carpet. |

| Material | Polyester, PP, Wool or Customized. |

| Technics | Needle punched nonwoven. |

| Thickness | 1-15 mm or Customized. |

| Weight | 60~1000gsm or Customized. |

| Width | Within 3.2m. |

| Roll Weight | Around 35kg or Customized. |

| Color | All colors are available(Customized). |

| Length | 100 m/roll or Customized. |

| Packaging | Plastic packing outside,scroll in the roll. |

| Payment | T/T,L/C |

| Delivery time | 14-30 days upon receipt of 30% deposit. |

| Price | Reasonable price with high quality. |

| Capacity | 5~6 tons per 20ft container; 12~14 tons per 40HQ container. |

| Non woven Fabric Usage: Our products are widely used in every field of modern society .Such as electric blanket,bedding, car interior, bags, mask, hats, clothes, shoecover, apron,cloth, packaging material, furniture, mattresses, toys, clothing, filter fabric, filling materials, agriculture, home textile,garment, industry, interlining and other industries. | |

***Nonwoven Application***

1. Eco Bags: Shopping bags, suit bags, promotional bags, gift bags, tote bag, etc.

2. Home Textiles: Table cloth, disposable cloth, furniture upholstery, pillow & sofa cover, spring pocket, mattress and quilt, dust cover, storage box, wardrobe, one-time hotel slippers, gift packing, wall paper, etc.

3.Interlining: Shoes, garments, suitcase, etc.

4. Medical/ Surgical: Surgery cloth, operation gown and cap, mask, shoe cover,etc.

5. Agriculture: UV treated products used in agriculture, plant bag, keep fruit warm cover, crop

cover/mulch,agricultural antifreeze tents,etc.

6. Car/ Auto cover and upholstery

****Needle Felts****

Basically, five technologies are applied to form nonwovens. In this context, needle punched nonwovens - also called Needle Felts - are still the most important technology for transforming fibers into a fabric. The estimated global share of needle punched nonwovens is 30 percent. Needle punching is a very traditional method of forming nonwovens and is especially suitable in terms of flexibility, quality and product diversity. Bonding using needling requires no water and consumes little energy. It has universal applications, a high degree of automation and a high production efficiency with low personnel requirements.

Product Showcase

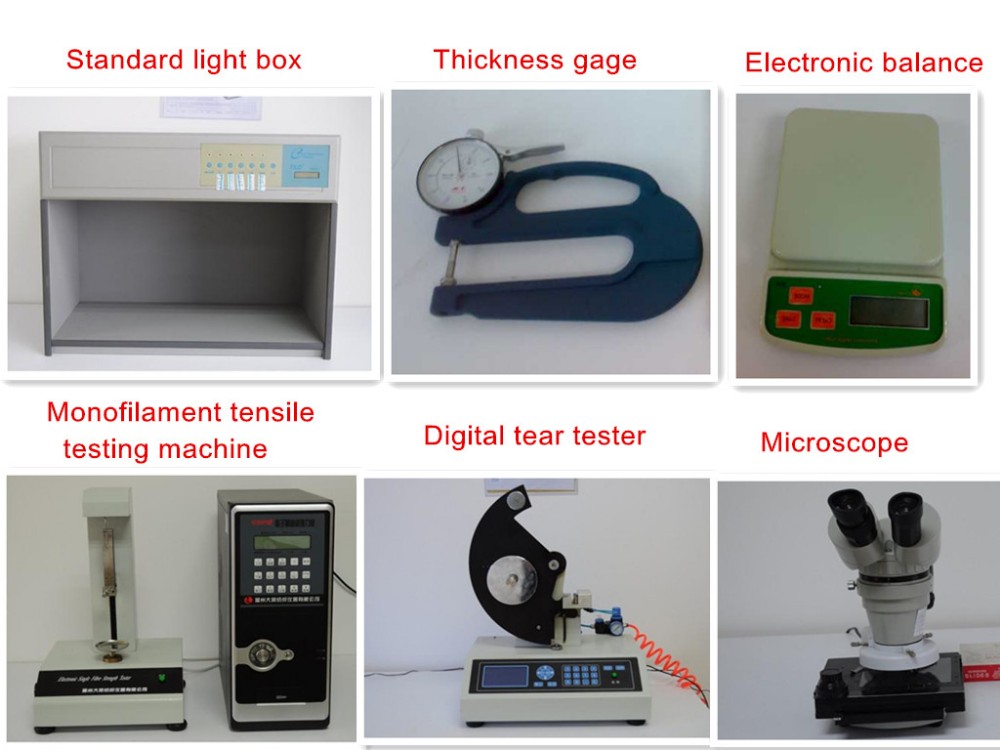

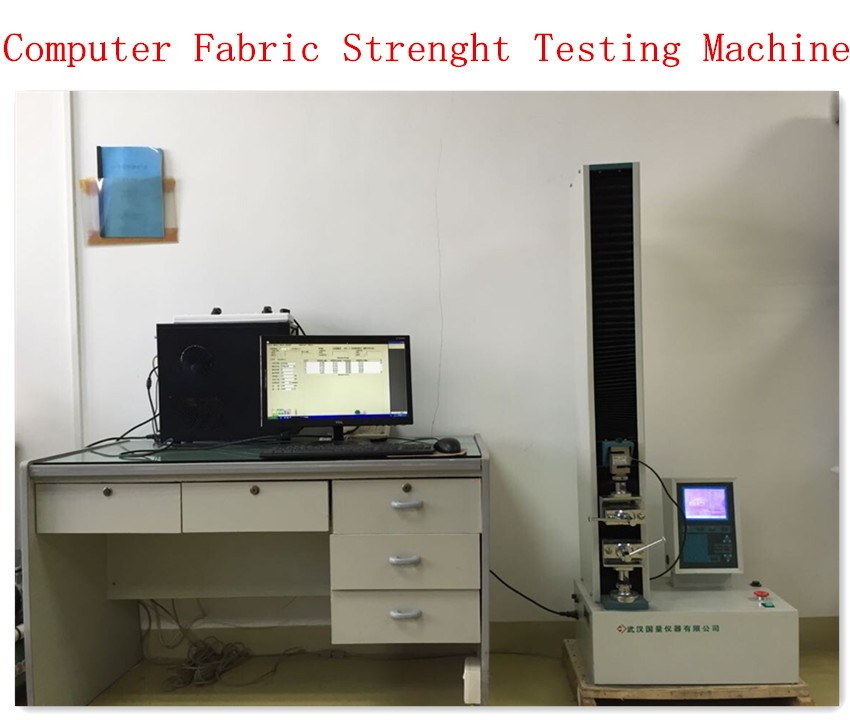

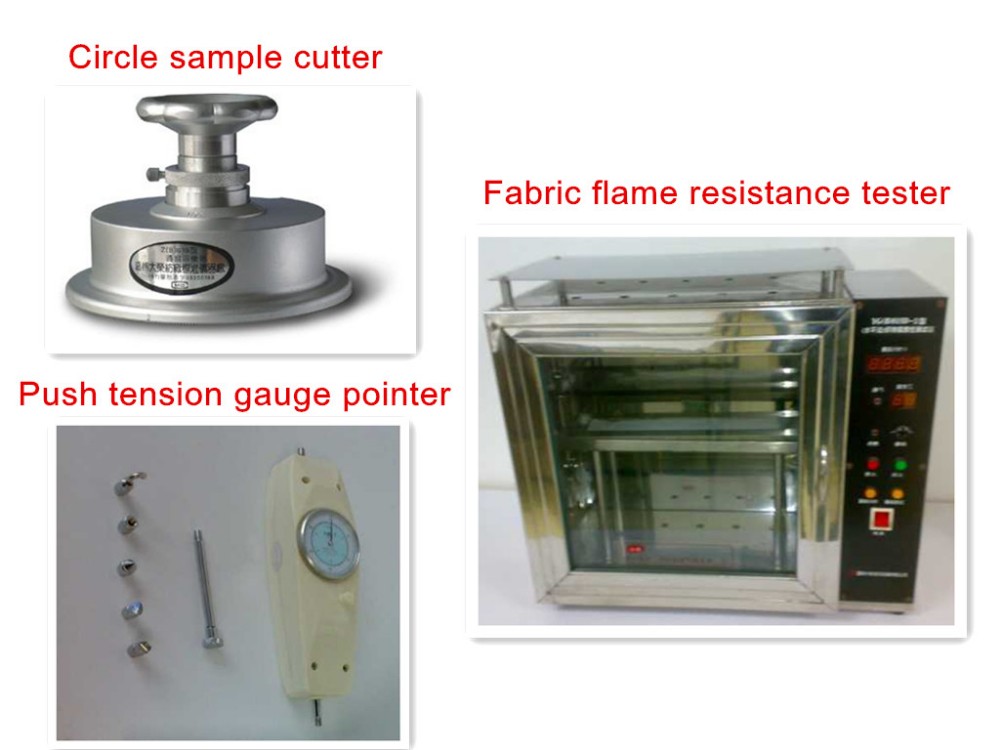

Testing Instruments

Production Line

Related articles

What is nonwoven fabric? And where is the application of nonwoven fabric?

Zer da materialaren ehuna? Eta non oihal materialaren aplikazioa da?

What are the advantages of nonwoven fabric?

Unsa ang mga bentaha sa nonwoven panapton?What is the difference between nonwoven st-free cloth?